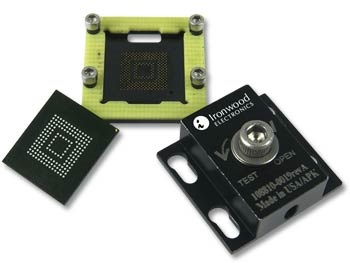

Ironwood Electronics continues to design and manufacture new Grypper Y test sockets for industry standard embedded multimedia card (eMMC)/Universal Flash Storage (UFS) memory devices. Ironwood Grypper socket, part number 113036-0003, allows testing of the newest generation (UFS) 153 BGA form-factor and all the  Source: Ironwood ElectronicseMMC devices as well.

Source: Ironwood ElectronicseMMC devices as well.

The socket will fit the 11.5 x 13 mm device size and will also allow smaller device sizes with the use of a drop-in alignment frame for the smaller devices. The Grypper Y socket typically will fit into to the same location/PCB footprint as the device allowing development and failure analysis. Although the socket body is larger than the device, the socket area around the device size is cantilevered allowing for most discrete device to fit under the cantilever. This socket is surface mounted using standard soldering methods. Force required for device insertion is preset by springs in the lid to approximately 25 g/contact.

To test a device simply insert it into the socket and slide the "KeyLock" lid on to the socket. The spring loaded press in the lid is released using a common hex driver. The Y shape geometry of the contact gently contacts the solder balls of the device allowing hundreds of insertions. This Grypper Y socket also has excellent electrical performance of -1 dB insertion loss up to 40 GHz.

The socket is available in three configurations, and sockets with a RoHS solder ball (SAC 305) replicate the device for attachment. The socket configured with SnPb solder balls allow easy reflow/attachment onto a PCB that already has components mounted. The lower melting temperature of the SnPb solder will not affect any adjacent components that might be close to the target area where the socket is to be placed. The socket can also be purchased with NO solder balls. No solder ball version requires the use of a 0.2 mm thick stencil for the correct amount of solder paste allowing any type of solder paste the customers lab might use for attachment.