Lithium metal batteries have been an exciting new prospect for battery technology in the last couple of years. From batteries inspired by spines, stretchable batteries, 4-Lithium-Ion batteries and more, it seems like lithium batteries are the future of electronic power. Researchers have been calling lithium metal batteries a promising candidate for high-density energy storage in smart devices and electronics for years.

This is dendrite mitigation for lithium batteries. (Source: Arizona State University)

This is dendrite mitigation for lithium batteries. (Source: Arizona State University)

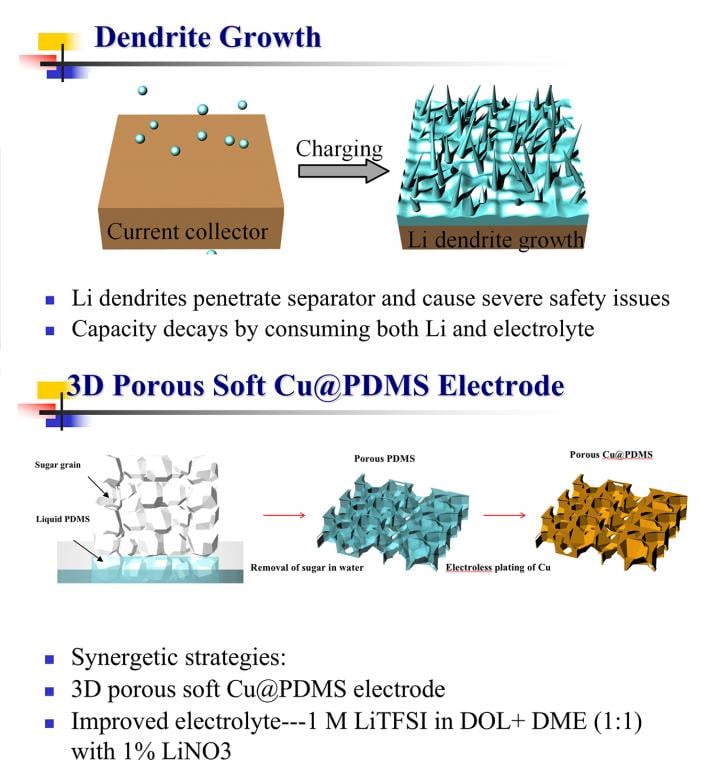

While these batteries are promising, they are not without their problems. The biggest issue keeping lithium metal batteries from wider use is the often uncontrolled dendrite growth. When a battery has dendrites, the result is poor recharge capability and safety hazards.

Dendrites are needle-like growths that show up on the surface of a lithium anode. Dendrites result in side reactions that lower the energy density and that can sometimes cause shorting of electrodes -- a huge safety hazard.

Arizona State University researchers found that making lithium-ion batteries using a 3D layer of polydimethylsiloxane (PDMS, also known as silicon) lowers the chance of dendrite growth, which in turn extends battery life and lowers safety risks. These discoveries are relevant for lithium-ion, lithium-air and metal-anode based batteries.

Hanquing Jiang, a professor from Arizona State University’s School for Engineering of Matter, Transport and Energy and lead researcher on the paper, said, “Almost all metals used as battery anodes tend to develop dendrites. For example, these findings have implications for zinc, sodium and aluminum batteries as well. We already know that tiny tin needles or whiskers can protrude out of tin surfaces under stress, so by analogy, we looked at the possibility of stress as a factor in lithium dendrite growth."

During initial research, the team added a layer of PDMS to the bottom of the battery anode. This was the first step that significantly lowered dendrite growth. This was directly related to the fact that stress from the lithium metal is relieved from the wrinkles that the PDMS forms. This discovery gave the researchers more insight into how dendrite growth works.

Through this research, the group found out how to utilize dendrites to extend lithium battery life and maintain high energy density. The key to doing this is giving the PDMS a 3D form with plenty of surface area.

"Envision sugar cubes that contain a lot of small internal pores," explained Jiang. "Inside these cubes, the PDMS forms a continuous network as the substrate, covered by a thin copper layer to conduct electrons. Finally, lithium fills the pores. The PDMS, which serves as a porous, sponge-like layer, relieves the stress and effectively inhibits dendrite growth."

"By synergistically combining with other lithium dendrite suppression methods such as new electrolyte additives, the finding has broad implications for making lithium-metal batteries a safe, high-density, long-term energy storage solution," said Professor Ming Tang, a research team member at Rice University. "Potential applications range from personal electronic devices to powering electric cars for exceptionally longer periods to being the backup electric supply for solar power grids."

The paper on this research was published in Nature Energy.